Becoming an Inventory Controller is easy with logistics and business administration qualifications. However, lots of people educated in other fields also choose their careers as Inventory Controllers. To become an Inventory Controller, you must be ready with enough stock handling and computer skills.

In this article,

Some positions function similarly to inventory controllers. Don’t get confused with Inventory Specialist, Inventory Officer, Inventory Clerk, Inventory Coordinator, or Inventory Incharge job positions. All of their basic roles are similar only the seniority level may be different. It depends on the logistics work orientation of the organization.

How to become an Inventory Controller

To become an Inventory controller obtain the following basic requirements,

- Qualification: Graduation in commerce, logistics, business management, or a similar education stream.

- Experience: Minimum 2 years extry level experience in logistics, retail, warehousing, stock keeping, or similar

- Skill Set: Good knowledge of ERP systems, stock handling, spreadsheets, and warehouse equipment (ie. Forklifts)

Reputed companies expect more than this when selecting the best candidate. To get chosen by a good company for this position you will need more exceptional skills such as inventory management, analytical & logical thinking, and problem-resolution skills.

Here is an example of one opening for the position of Inventory Controller posted on Linkedin Jobs,

Researching company requirements will give you more idea of how to become an Inventory Controller.

Skills required for Inventory Controller Jobs

In addition to basic qualifications and requirements, you will need the following skills, which will boost your job application strength.

- Knowledge of supply chain, procurement, purchase order processing

- Ability to accurately count, reconcile and find defects in stock

- Ability to produce timely stock reports

- Ability to correctly record stock movement and produce related documents

- Excellent MS office, and Excel knowledge

- Ability to receive and dispatch material/stock

- Strong analytical and problem-resolving skills

- Knowledge of warehouse equipment and their basic maintenance

- Knowledge of ERP (Enterprise Resource Planning) software suites such as NetSuite, SAP, Oracle ERP, MS Dynamics 365 ERP

As an Inventory controller, you will need good knowledge of the supply chain and its working. As a company needs various raw materials to be used in production. An uninterrupted supply of raw materials is expected in every company. To maintain stock levels procurement procedures needed to be established with the suppliers. While doing this your job is to search for a new supplier or re-order from the existing supplier. This procurement process goes through various phases such as

1. Finding understock items / raw material

2. Inquiring quotations from the new & old suppliers and sorting them

3. Getting approval for quotation from the higher management

4. Preparing purchase order (PO) & getting approval

5. Placing an approved purchase order

6. Tracking expected consignment

7. Receiving & verifying consignment, invoices, goods quantity & quality

8. Producing related documents (ie. Goods Receipt Voucher)

9. Recording transactions (inwards & outwards) in ERP System

10. Issuing raw materials for production (in a factory environment)

While becoming an Inventory Controller, the ability to accurately count stock items by doing frequent cycle counts is expected. Many financial decisions rely on the status of Inventory. Accurate inventory stock status must be reported to the higher management so they will take budget & purchase-related decisions. In this position, your job will be to schedule and take frequent cycle counts to measure balance stock items. During this count, you should detect stock differences. The reason behind stock anomaly has to be addressed properly so it can be avoided in the future.

Once the stock is counted and verified you have to prepare timely stock reports. It could be an ERP system generated or prepared in a spreadsheet. There are many types of stock reports which could be asked to prepare. Following are some key types of inventory reports,

- Stock level reports/material reorder point report

- Inventory performance report

- Inventory forecasting report

- Inventory aging report

- Inventory valuation report

- Inventory analytic report of purchase, sales

Recording each and every stock movement is necessary for this job. Stock movement means what comes inward from the purchase and what goes outwards as sales. Without recording this we cant determine what is going on in the company. In a factory production environment, you also have to record daily raw material issue/return and then produced goods. All these movements are recorded on physical documents and then in the ERP system. These documents are checked and verified by related staff and then gets signed by supervisors.

Microsoft office and excel skills are needed in this job. As an Inventory controller, you should know various MS Excel formulas and tricks to quickly work on large data and produce relevant reports. After collecting data from the floor, it must be analyzed and validated in a spreadsheet so it can be converted into meaningful formats. Excel formulas and micros can do hours jobs in minutes. To make reports you should know how to present data in charts and graphs.

Your job will not be limited to the desk only. You must be able to load and unload material whenever necessary. Receiving material consignment includes unloading and shifting that material to the warehouse racking system. And dispatching includes bringing finished goods into the loading area and then loading them properly into the container or shipping vehicle.

You will not be alone in this job, the loading-unloading team will be with you. You will be in charge of that team. The inventory controller is also responsible for the training of staff, following SOPs (standard operating procedures), applying safety measures, and the basic maintenance of lading-unloading equipment.

In addition, the Inventory controller should have basic operating & maintenance knowledge of warehouse equipment. This equipment includes power pallets, forklifts, an automated racking system, emergency doors, barcode printers, etc. It is expected to drive power pallets or forklifts whenever necessary.

A very important and most demanded skill set required for this position is practical knowledge of various ERP systems. A company sometimes includes ERP experience in must-have requirements. There are several ERP systems in the market which are mostly being used by companies. SAP, Oracle NetSuite, and MS Dynamics 365 ERP are one of them. As an Inventory controller, you have to work on one of those ERP systems. This system will allow you to do all computer-based document recording, and report generation tasks.

Career path of Inventory Controller

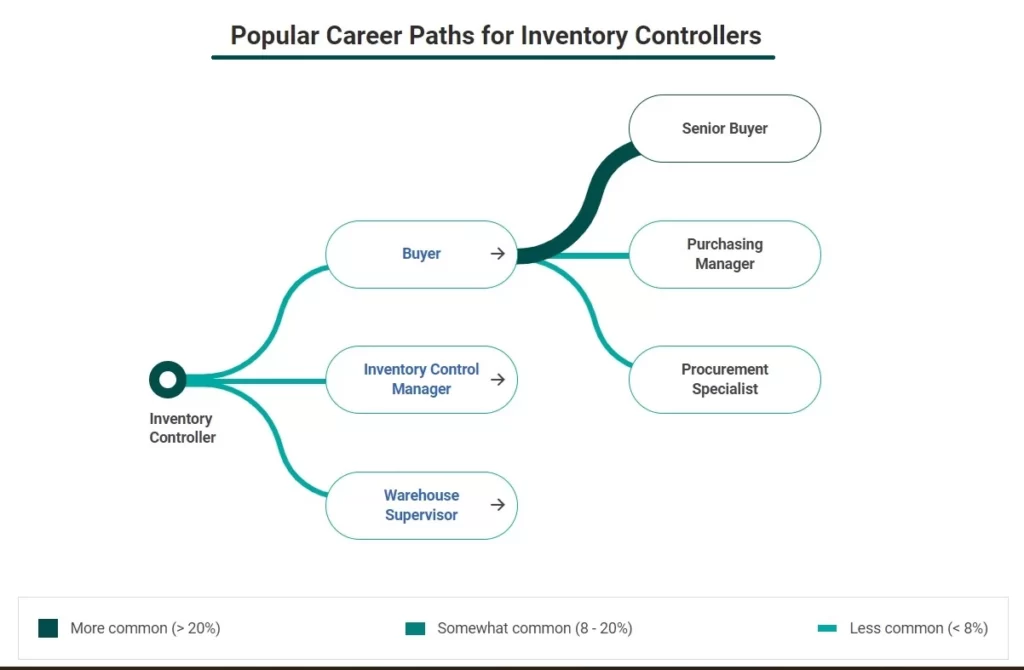

It is clear that you have to enter this career by starting an entry-level job. After 2 years of experience, you can jump to the Inventory Controller position either by getting promoted or by changing employers. After enough experience and the additional benefits of a master’s degree, your career as an Inventory Controller may lead you to one of the following positions,

- Buyer/purchaser then purchase manager.

- Inventory control manager

- Warehouse supervisor then Warehouse manager

As per payscale.com after becoming an Inventory controller in the USA you could earn between 35K -75K USD per year. The average pay scale is 55,000 USD per year. It increases with promotions and additional benefits. The pay scale varies in different countries.