Thinking of choosing Inventory Controller as your career? It could be a good choice if you compare your passion and skills with the Inventory Controller job description. Here on this blog, you will learn a lot about this profession. It will help you to find out,

What is an Inventory Controller?

An Inventory Controller is a mid-career professional in the supply chain & warehouse management environment. The job role is to control, record, count, and report the company’s inventories in the form of stock and goods.

An inventory controller is responsible for handling inventory-related tasks in the warehouse of an organization. The job can be further termed as a stock keeper or stock controller. Its primary duty is to keep adequate stock levels at the time of production & supply demand.

The inventory controller’s main job is to maintain accurate levels of inventory, reporting them on a monthly or weekly basis. The duty also includes lots of inventory-related work such as labeling and recording inwards and outwards. He is in charge of inventory control and management operations such as,

- Specification, Labelling & Classification of inventories

- ABC and other analysis

- Material/Goods costing

- Maintaining safe buffer stock levels

- Weekly/Monthly cycle count

- Various stock report generation

- Stock inward & outward recording in IMS

- Handling damaged/waste stock

- Applying warehouse SOP’s

- Forecasting material consumption and demands

- Auditing warehouse inventory for financial reports. etc

An inventory controller reports to their superiors such as the Inventory Manager, Store Manager, Procurement/Purchase, or Sales Head. Often he can have some people on his team such as store assistants, forklift operators, and data entry clerks.

What do Inventory controllers do?

Inventory Controllers manage and control a company’s inventory levels by monitoring incoming and outgoing goods. They use resource management software such as ERPs to plan and analyze purchases and sales delivery schedules, and coordinate stock item counts.

Out of lots of inventory control and management tasks following are some key responsibilities of an inventory controller.

- An inventory controller is responsible to monitor inventory levels and replenishing stock as needed.

- Coordinates with the vendors and suppliers and negotiates to ensure the quality of stock purchases.

- Coordinates the purchase and logistics department for purchase orders, stock transfers, deliveries, tagging, and processing.

- Forecasts supply and demand to ensure adequate stock availability.

- Prevents both excessive and out-of-stock (OOS) situations.

- Analyses and reviews supply chain data to identify and resolve issues.

- Generates various stock and analysis reports.

- Performs regular stock checks and reporting tasks.

- He has to work on ERP systems to maintain and update records of purchase orders, pricing reports, and inventory records.

Other responsibilities include logging all inventory purchases, assisting in the shipping & receiving of new shipments, conducting physical counts to make sure no theft is occurring, and taking measures to prevent loss.

Inventory controllers typically work in a company warehouse setting environment. And this environment may vary which depends on the nature of the inventory. Such as chemicals, medicines, frozen foods, etc. He may have to perform physical tasks such as lifting and moving pallets and items with or without forklifts as needed.

To become an inventory controller, one must have a high school diploma or equivalent or higher graduation in supply chain, commerce, and logistics. Math and computer excel skills are essential, as the inventory controller works with inventory levels.

1-2 years of warehouse experience is usually required by employers. Additionally, he must be able to work well independently with minimal supervision, but they should also be able to work well in a team setting with other warehouse staff such as operators and assistants.

To ensure career success as an inventory controller, you should be highly organized and have detailed knowledge of ERP, supply chain management software, and practices. A top-notch inventory controller will be able to accurately forecast inventory requirements and has excellent logistical abilities.

What is the salary of the Inventory Controller?

According to salary.com, The average Inventory Controller salary in the United States is between the range of $83,960 and $110,450 per year.

Where the research is done on indeed.com from 224 reported salaries, the average salary for an inventory controller is $63,088 per year in the United States.

The salary of Inventory Controllers varies in various countries and business sectors. What will you get, depends on many factors such as education, certification, extra skills, and years of experience.

Salary grows with experience and seniority level. As you have a good chance of growing your career to further posts such as Inventory or Warehouse manager.

Learn more about inventory control specialist salary.

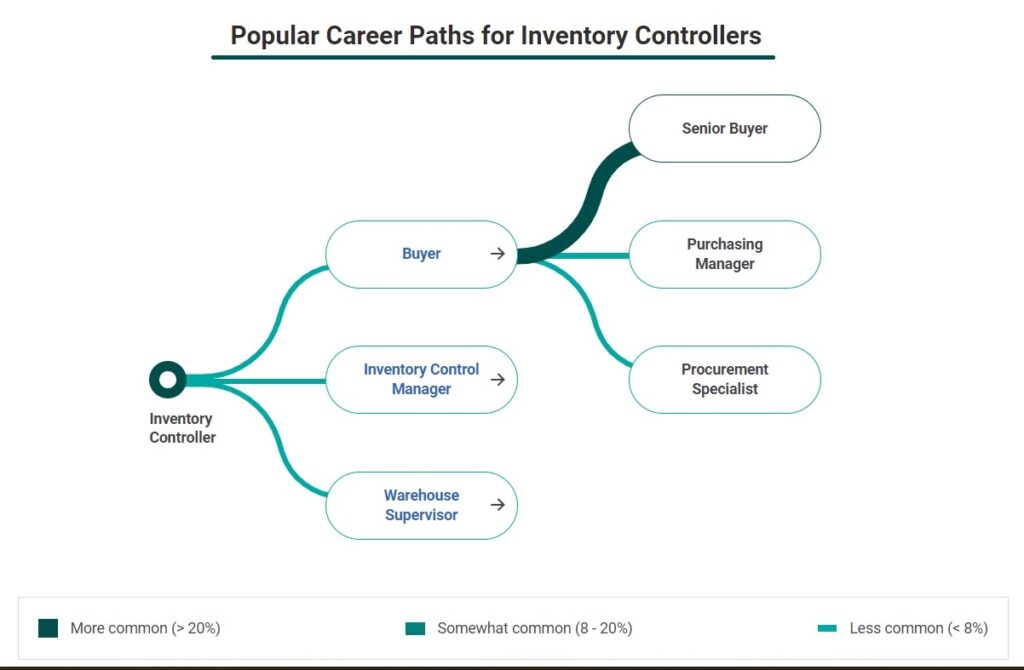

What is the career path of an Inventory Controller?

To begin a career path as an inventory controller you should hold graduation in commerce or the supply chain field. However, you can get promoted to this position from the lower posts after gaining good experience.

You can begin your career as an Inventory clerk or storekeeper or ERP data entry operator. Which will lead you through the post of Inventory Controller.

Your career has the potential to become,

– Inventory / Store / Warehouse Manager

– Procurement Manager / Head

– Senior Inventory Analyst/ Controller /Supervisor