Inventory is not just stock sitting in a warehouse — it is working capital invested in the business. When inventory is poorly managed, cash gets blocked, space is wasted, and operations suffer. Whether it is a manufacturing plant, cold storage, or distribution center, effective inventory control begins with one core discipline: material classification.

As an inventory controller, my first priority is to understand every SKU in the system. Without knowing what types of materials exist, how they behave, and how critical they are, inventory control turns into guesswork. You cannot control what you do not clearly understand.

Human beings cannot manage thousands of items individually. We rely on patterns. The same principle applies to inventory. When materials are grouped logically, thousands of SKUs become a few manageable categories, making control practical instead of overwhelming.

In real operations, inventory problems rarely start with counting errors. Most issues — shortages, overstock, expiries, and dead stock — originate from poor material classification.

What Is Material Classification?

Material classification is the process of grouping inventory items based on common characteristics such as value, movement, usage, criticality, or storage requirements.

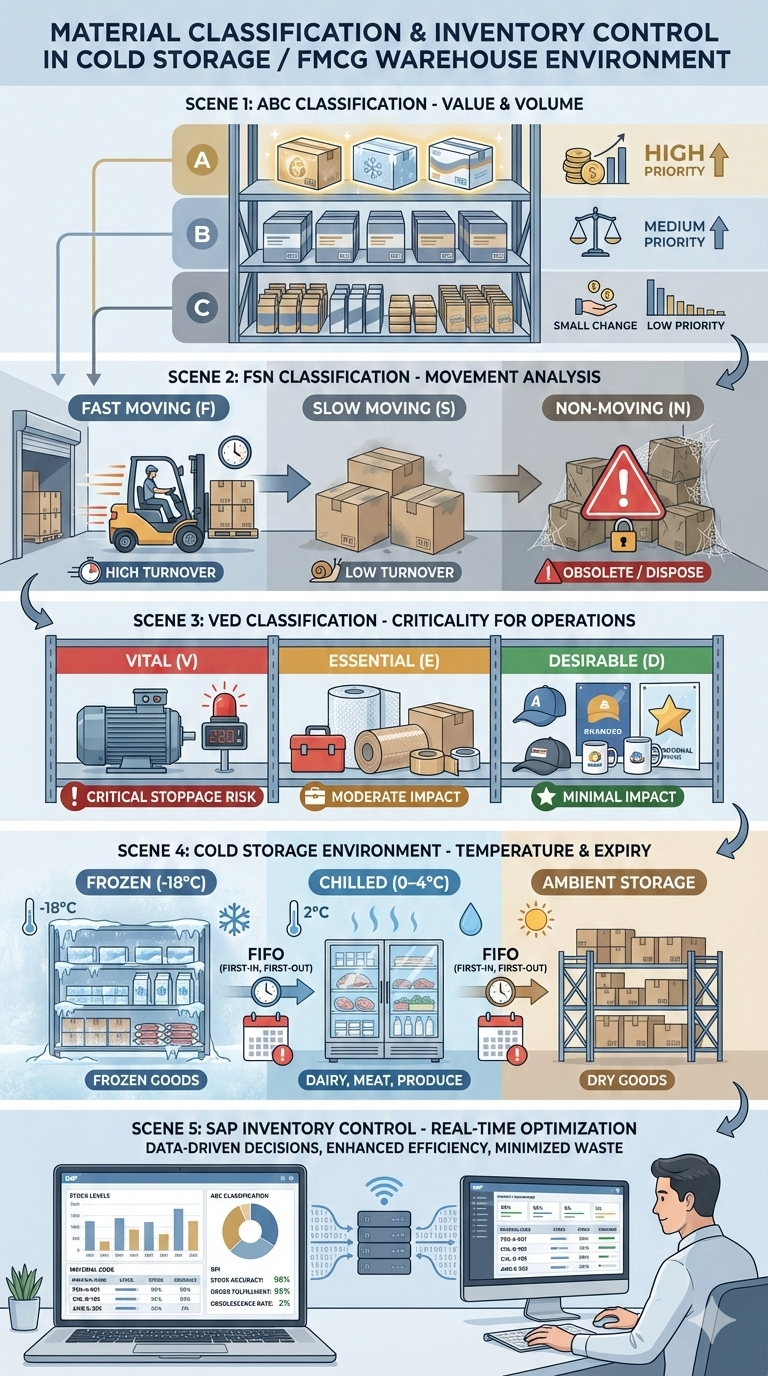

In daily warehouse and supply chain operations, commonly used classifications include:

- Material stage: Raw Material, Work in Progress (WIP), Semi-Finished, Finished Goods

- ABC classification: Based on annual consumption value

- FSN classification: Based on movement (Fast, Slow, Non-moving)

- VED classification: Based on operational criticality

- HML classification: Based on unit price

- Storage-based classification: Ambient, chilled, frozen, hazardous

- Function-based classification: Production, Maintenance, Repair & Operations (MRO)

The purpose is simple:

👉 Not all materials require the same level of control.

Why Classification Directly Impacts Inventory Control

Inventory control has three core objectives:

- Right quantity

- Right time

- Minimum cost

When materials are not classified, every item is treated equally. This leads to excessive monitoring of low-value items, neglect of critical materials, high working capital blockage, and frequent stockouts or expiries.

Proper classification ensures that control efforts are focused where the financial and operational risk is highest.

ABC Classification: Controlling What Matters Most

Consider a warehouse managing 1,000 SKUs with an annual consumption value of ₹10 million.

After ABC analysis:

- A items: ~10% of SKUs contributing ~70% of value

- B items: ~20% of SKUs contributing ~20% of value

- C items: ~70% of SKUs contributing ~10% of value

Without ABC classification, all items receive the same review cycle, approval process, and safety stock logic — wasting time and resources.

With ABC classification:

- A items are monitored closely with tight reorder levels

- B items are reviewed periodically

- C items are controlled with relaxed frequency

This approach delivers strong control over most of the inventory value while reducing operational effort. Inventory control becomes strategic rather than mechanical.

FSN Classification: Making Dead Stock Visible

FSN classification divides materials into Fast-moving, Slow-moving, and Non-moving items.

Imagine a spare part with an annual consumption of 120 units but a closing stock of 880 units. At an average consumption of 10 units per month, this represents more than seven years of inventory.

Without FSN classification, such stock remains hidden on reports. With FSN classification, it is clearly identified as Non-moving, triggering corrective actions such as stopping procurement, transferring stock, substitution planning, or liquidation.

FSN classification prevents inventory from silently draining working capital.

VED Classification: Managing Operational Risk

VED classification is critical for maintenance, engineering, and FMCG operations.

- Vital items can stop production if unavailable

- Essential items allow limited delay

- Desirable items have minimal operational impact

Treating all materials the same can result in production loss due to the unavailability of vital parts, while low-risk items accumulate unnecessarily.

VED classification shifts inventory control from quantity-focused to risk-focused, ensuring availability where failure is costly.

Storage-Based Classification and Physical Control

Material classification also determines how inventory is physically handled in the warehouse.

Frozen, chilled, ambient, and hazardous items each require different storage rules, counting frequencies, and expiry controls. A frozen SKU with a 90-day shelf life needs stricter FIFO discipline than an ambient item with a two-year shelf life.

Without proper classification, FIFO violations increase, expiry losses rise, and inventory accuracy declines. With structured classification, warehouse discipline improves and losses are minimized.

Understanding Inventory Types

To manage inventory effectively, it is essential to understand its basic types:

- Raw Materials – Inputs before production

- Work in Progress (WIP) – Materials in the production process

- Finished Goods – Completed products ready for sale

Depending on the business model, inventory may also include packing materials, components, MRO items, safety stock, transit inventory, excess stock, and rejected or damaged goods. Each category requires a different control approach.

How Classification Improves Inventory Performance

Effective material classification directly improves:

- Inventory turnover

- Carrying and storage costs

- Stock accuracy

- Service levels

- Working capital utilization

Reducing excess stock in non-moving or low-value categories frees cash that can be reinvested in critical and fast-moving items — without increasing headcount or system costs.

Practical Example: Food Manufacturing

In a chicken burger production operation, materials can be clearly classified as:

- Raw materials: Raw chicken

- Ingredients: Spices, oil, soya, rusk

- WIP: Marinated or mixed chicken

- Packing materials: Wrappers, cartons

- Finished goods: Packed burger patties

This clarity simplifies planning, purchasing, storage, and control across the operation.

Final Thoughts

Inventory control is not about counting more — it is about controlling smarter.

Material classification brings structure to complexity. It tells inventory teams where to focus, what to protect, and what to release. Although it may not appear urgent, classification is the foundation on which every reliable inventory system is built.

If inventory is the lifeblood of operations, material classification is the system that keeps it flowing smoothly.