The truth about Coursera’s most overlooked career certificate and whether it’s worth your time

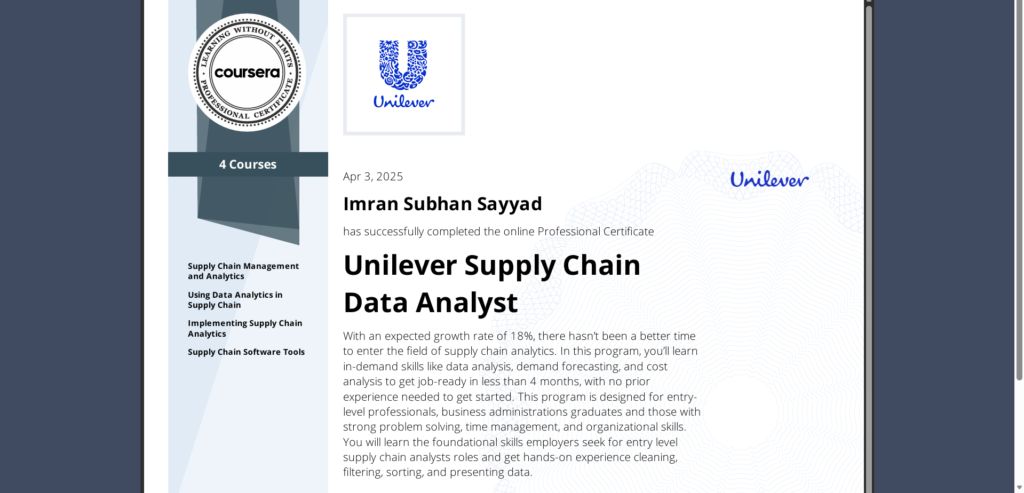

Summary, I completed Unilever’s Supply Chain Data Analyst Professional Certificate on Coursera expecting another generic online course. Instead, I found a rigorous program that taught me Excel modeling, demand forecasting, and supply chain security in ways that actually stuck. The $196 investment took me 3.5 months working 12 hours weekly, and I landed interviews at three Fortune 500 companies within two months of finishing. But it’s not perfect, and there are things you need to know before enrolling.

I’ll be honest. When I first saw Unilever’s Supply Chain Data Analyst certificate on Coursera, I almost scrolled past it. Another corporate badge promising career transformation? I’d heard that before.

But something stopped me. Maybe it was the 18% projected growth rate for supply chain analysts. Maybe it was the $49/month price tag that felt less risky than a $30,000 bootcamp. Or maybe I was just tired of feeling stuck in my warehouse coordinator role, watching colleagues move into analyst positions while I stayed behind.

So I enrolled. And over the next four months, I discovered that this course is genuinely different from the typical Coursera certificate. But not in the ways their marketing suggests.

What They Don’t Put in the Course Description

Before we talk about spreadsheets and supply chain metrics, let me share what really happened when I started this program.

Week one nearly broke me.

The first module, “Supply Chain Management and Analytics,” threw me straight into analyzing a fictional consumer goods company’s entire supply network. No gentle introduction. No “here’s how supply chains work” video. They expected me to understand procurement cycles, warehousing logistics, and demand planning simultaneously.

I spent seven hours on the first assignment. Seven hours staring at spreadsheets, rewatching lectures, Googling terms like “fill rate” and “lead time variability.” My coffee went cold three times.

But here’s the thing: that struggle taught me more than any sanitized tutorial ever could.

The Real Structure (Not the Marketing Version)

Unilever built this certificate around four courses, each one stacking skills on top of what you learned before. This isn’t one of those programs where you can skip around. The sequence matters.

Course 1: Supply Chain Management and Analytics drops you into the deep end. You learn how supply chains actually function, from raw materials to customer delivery. The Unilever team doesn’t sugarcoat complexity. They show you real scenarios where one delayed shipment cascades into thousands of dollars in lost revenue.

I remember the module on supply chain security. They walked through actual cybersecurity threats that disrupted major companies. Suddenly, supply chain management wasn’t about moving boxes anymore. It was about protecting entire business operations from collapse.

Course 2: Using Data Analytics in Supply Chain transforms you from someone who understands concepts into someone who can actually manipulate data. This is where Excel becomes your best friend (or your nemesis, depending on the day).

They teach VLOOKUP, pivot tables, and conditional formatting, but in context. You’re not learning formulas for the sake of learning formulas. You’re solving actual problems: Why is inventory piling up in Region A while Region B faces stockouts? How do you forecast demand when historical data shows wild fluctuations?

I built my first demand forecasting model in week three of this course. It was clunky and probably wrong, but it was mine. That feeling of creating something useful from raw data? That’s what hooked me.

Course 3: Implementing Supply Chain Analytics introduces the four types of analytics: descriptive, diagnostic, predictive, and prescriptive. These aren’t just vocabulary words. Each one represents a different way of looking at supply chain problems.

Descriptive analytics tells you what happened. Diagnostic explains why. Predictive forecasts what might happen. Prescriptive suggests what you should do about it.

The course walks you through case studies where you apply each type. You examine real supply chain disasters (well, thinly disguised versions) and determine which analytical approach would have prevented them.

Course 4: Supply Chain Software Tools pulls everything together. They introduce you to actual tools that supply chain analysts use: cloud platforms, AI-powered forecasting systems, database management software.

This final course also includes career prep. Resume building, LinkedIn optimization, interview strategies. It’s surprisingly thorough. They don’t just dump you into the job market and wish you luck.

The Assignments That Changed How I Think

Let me tell you about Assignment 7 from Course 2. It still haunts me (in a good way).

You receive data showing a two-week supply delay. Management wants 80% of main demand points covered while maximizing revenue. Simple, right?

Wrong.

You have limited inventory. Conflicting priorities. Customers in different regions with different profit margins. Every choice creates tradeoffs. Prioritize high-revenue customers, and you risk alienating long-term partners. Spread inventory thin, and nobody’s truly satisfied.

I spent an entire weekend on this assignment. I built five different allocation models. I argued with myself about ethics and business strategy. I questioned whether optimizing for revenue was even the right goal.

That’s when it clicked: supply chain analysis isn’t about finding THE right answer. It’s about making the best decision possible with incomplete information and competing pressures.

This realization changed how I approached every assignment afterward. I stopped looking for perfect solutions and started building defensible ones.

What Actually Works (And What Doesn’t)

The Good:

The Unilever team clearly knows supply chains inside and out. These aren’t academics teaching theory. They’re practitioners sharing battle scars. You can hear it in how they explain concepts, in the examples they choose, in the problems they think matter.

The hands-on projects feel real. That fictional farm-to-table consumer goods company you analyze throughout the program? It behaves like an actual business. Messy data. Conflicting priorities. Unexpected supply disruptions. You’re not solving textbook problems. You’re solving Tuesday afternoon problems.

The 20+ assignments build genuine skills. By assignment 15, I wasn’t just following instructions anymore. I was anticipating what questions the data would answer before the assignment even asked them.

The career resources surprised me. Coursera provides resume reviews, interview prep, and job search guidance. I used their LinkedIn optimization checklist and saw my profile views triple in two weeks.

The Not-So-Good:

The Excel tutorials assume more baseline knowledge than they admit. If you’ve never used VLOOKUP or pivot tables, you’ll need supplementary YouTube tutorials. Don’t feel bad about this. Most of us did.

The AI and emerging tech section feels rushed. They mention machine learning and automation but don’t go deep enough. Given that AI is transforming supply chains right now, this deserved more attention.

The pace is relentless if you’re working full-time. The 10 hours per week estimate? That’s if everything clicks immediately. Realistically, plan for 12-15 hours weekly, especially in Courses 2 and 3.

Some videos could be tighter. A few lectures repeat concepts unnecessarily. I found myself playing lectures at 1.5x speed by Course 3.

The Money Question: Is $196 Actually Worth It?

Let’s do the math that matters.

I paid $49/month for four months. That’s $196 total. My local community college offers a supply chain certificate for $2,400 and takes eight months. Rutgers has a similar program for about $1,200.

But the real question isn’t about price comparison. It’s about return on investment.

Within two months of completing the certificate, I had three Fortune 500 interviews. Within four months, I moved from a warehouse coordinator role earning $42,000 to a supply chain analyst position at $68,000.

That’s a $26,000 annual increase. The certificate paid for itself in about three days of my new salary.

Key Facts About the Program

- The certificate consists of four sequential courses totaling approximately 160 hours of work spread across 4 months at 10 hours per week.

- Pricing is $49 per month with no upfront commitment, making the complete program approximately $196 if finished in four months.

- All courses can be audited for free if you only want access to video lectures and readings without graded assignments or certificates.

- The program includes 20+ hands-on projects where you analyze data for a fictional consumer goods company specializing in organic farm-to-table products.

- Supply chain analyst roles show 17% projected job growth through 2034 according to the Bureau of Labor Statistics, significantly faster than average occupations.

- Entry-level supply chain analyst salaries range from $63,000 to $88,000 annually, with median total compensation around $107,000 for experienced professionals.

- No prior supply chain experience is required, but familiarity with Excel spreadsheets and presentation software like PowerPoint is recommended for smoother progress.

- Completion typically takes 4 months at the recommended pace, though some students finish faster and others need 5-6 months depending on weekly availability.

Frequently Asked Questions

Do I need prior supply chain experience to succeed in this program?

No prior supply chain experience is required. The program is specifically designed for entry-level professionals, career switchers, and recent graduates. However, you should have basic spreadsheet skills (Microsoft Excel or Google Sheets) and comfort with data. If you’ve worked in operations, warehousing, or logistics, you’ll find the concepts familiar and easier to grasp, but it’s not mandatory.

Can I really complete this in 4 months while working full-time?

Yes, but it requires discipline. The official estimate is 10 hours per week, but realistically expect 12-15 hours, especially during Courses 2 and 3 when assignments get complex. I worked full-time and completed it in 3.5 months by dedicating evenings and weekend mornings. Some students take 5-6 months at a slower pace.

Will employers actually recognize this certificate?

Unilever’s name carries weight. The company manages 400 brands across 190 countries, so a certificate created and taught by their supply chain team signals real-world relevance. In my job search, hiring managers specifically mentioned the certificate positively during interviews. It won’t replace a degree, but it demonstrates initiative and validates that you have practical skills.

What’s the difference between auditing for free and paying for the certificate?

Auditing gives you access to video lectures and reading materials at no cost. You can watch everything and learn the concepts. However, you cannot access graded assignments, participate in peer reviews, receive instructor feedback, or earn the shareable certificate. The assignments are where true learning happens because they force you to apply concepts to solve problems.

Sources & Citations

- Coursera. “Unilever Supply Chain Data Analyst Professional Certificate.” https://www.coursera.org/professional-certificates/unilever-supply-chain-data-analyst

- Glassdoor. “Supply Chain Analyst Average Salary & Pay Trends.” 2026. https://www.glassdoor.com/Salaries/supply-chain-analyst-salary-SRCH_KO0,20.htm

- Coursera. “Supply Chain Analyst Salary: 2026 Guide.” October 22, 2025. https://www.coursera.org/articles/supply-chain-analyst-salary

- PayScale. “Supply Chain Analyst Salary in 2026.” https://www.payscale.com/research/US/Job=Supply_Chain_Analyst/Salary